Meatballs as smart batteries

How Van Ballaert’s Butchery Embraced Smart Freezer Tech

What happens when a traditional butcher’s shop, where recipes are passed down for generations, meets the world of sensors, data, and smart algorithms? That’s exactly what I set out to discover with my very first pilot project at Slagerij Van Ballaert in Brecht.

Why Start Here? The Changing Energy Landscape

Figure 1: Over the past few years the installed solar capacity in Belgium increased from 5 to 11, while phasing out nuclear power plants from 6 to 4 GW (Source: De Tijd).

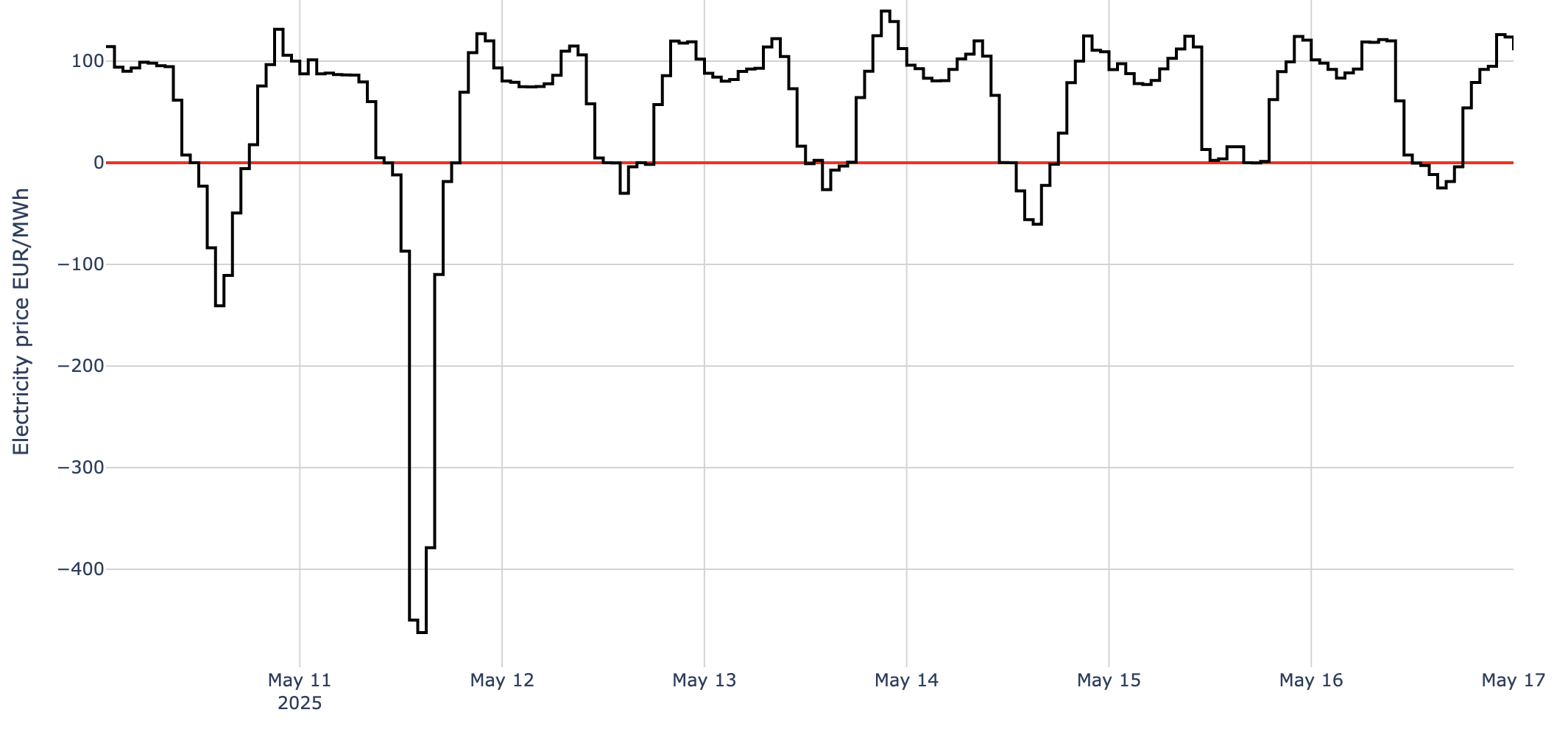

Belgium’s energy mix is changing fast. With more wind and solar power on the grid, electricity is greener than ever-but also less predictable. This means energy prices can swing wildly from hour to hour, depending on the weather and demand. The 11th of May the price even broke all time records at negative prices of -462 €/MWh.

Figure 2: EPEX Spot Belgium - day ahead price (Source: Entso-e)

On a sunny day prices typically fluctuate between -20 and 120 €/MWh at the EPEX (day-ahead) market. Day-ahead means that these prices are published the day before. So when having a dynamic contract you exactly know with 100% certainty what the price of electricity will be for each hour.

For businesses, this opens up a new opportunity: if you can be flexible about when you use electricity, you can save money and help use more renewable energy. Most companies think of batteries when they hear “flexibility”, however batteries are expensive. Instead why not use existing processes like large cooling cells to store cheap energy and save costs when prices spike?

From Handmade Hams to High-Tech Freezers

Van Ballaert has been part of the Brecht community since 1909. Their smoked hams, “baksaucisse”, and homemade charcuterie are local legends, made with care and the same family recipes for over a century. When Jef Van Ballaert agreed to try something new with his freezer, I knew we had the perfect mix of old and new.

The Experiment: Can a Freezer Think for Itself?

I started by installing a small IoT device and connecting it to the freezer’s Dixcell thermostat. Suddenly, we could see exactly how the freezer was behaving: temperature, setpoints, and energy use, all in real time. After a week of testing and some time-series data analytics and statistics, we better understand the system’s thermodynamics and can start optimising the cost.

In figure 6 and 7 can be seen that on average the energy consumption doubles when cooling from -20 to -25°C. However, this energy can be partly recovered when relaxing the setpoint to it’s original value. After a cooling period the freezer’s energy input is reduced by 30% for several hours compared to running steady state at the same setpoint of -20 °C. By planning cooling cycles during low-price periods and letting the freezer “coast” when prices spike, we can significantly cut costs.

Using linear programming, I calculated the most cost-effective schedule for the compressors and evaporators - while always staying within safe temperature limits. Every hour, the system could choose:

Cool down to setpoint of -25°C, or

Coast to setpoint of -20°C

This algorithm runs in the cloud and uses experimental data and day-ahead prices to decide on the optimal setpoint for each hour. With 24 hours per day and only two possible setpoints, that’s 2²⁴ or 16 777 216 possible combinations per day!

Figure 8: Cost benefit analysis of running with optimisation algorithm and dynamic pricing.

What Did We Learn?

The results of this proof-of-concept are:

After a big cooling cycle, the freezer needs 30% less energy for hours afterward compared to steady state at the same setpoint.

By timing these cycles to match low energy prices, we achieved 10–20% cost savings without compromising operational limits

Why This Matters (and What’s Next)

For Van Ballaert, the savings are welcome, but their energy bill is relatively modest and mainly driven by other electrical consumers that aren’t flexible. The real potential lies with bigger players — think warehouses, data centers, pharmaceutical cold storage, industrial manufacturing, or agro and large food producers—where this approach could deliver significant savings.

Get in touch and also use these data science optimization techniques and learn how I helped companies save millions.